Description

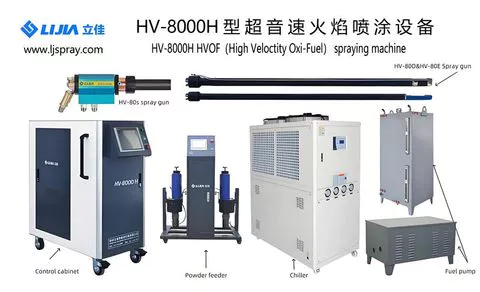

The company's research and development of HV-8000H supersonic flame spraying is a new type of HVOF system, using aviation-grade kerosene as the fuel system, is also one of the most popular kerosene fuel equipment in the world, the equipment has been praised by customers since its listing, and has been widely used in various thermal spraying industry enterprises at home and abroad. Its basic principle is to fully atomize the kerosene through the atomization nozzle to form a combustible mixture into the combustion chamber, and the ignition system ignites the high-temperature and high-pressure gas, which is ignited by the Laval nozzle to form a high-temperature and high-pressure supersonic flame flow, and the powder feeding system sends the powder material from the low-pressure area into the flame flow, and sprays it to the surface of the workpiece to form a high-quality coating after the heating is accelerated. HV-8000H spraying system is a spraying equipment developed on the basis of introducing, digesting and absorbing foreign advanced equipment and technology, and has a variety of significant characteristics compared with other HVOF.

HV-8000H equipment panel settings are all operated through the touch screen, with 12 powerful functional modules that are internationally leading, all kinds of common operations, information display and fault alarms are readily available, and are very in line with the user's operating habits, simple and easy to use, stable quality.

HV-8000H has many functions and features, and its advantages are mainly reflected in the following ten aspects:

1) Touch screen operation, the equipment design structure adopts a full closed-loop automatic control structure, and the gas is all controlled by the mass flow controller, and the flow can be monitored in real time and automatically reach the process set value.

2) The fuel used is kerosene (hydrogen and nitrogen are added to the inner hole spraying), and the combustion agent is oxygen, which is the safest combustion mode in the current market;

3) The structure of the spray gun is designed according to the principle of rocket generator, the maximum combustion chamber pressure is 150PSI, the flame flow speed is more than 2000m/s, and the output power is large and can be adjusted steplessly;

4) The spray gun adopts radial powder feeding, which makes the powder better dissolved and evenly distributed in the whole flame, which improves the covering efficiency and the quality of the coating;

5) With the function of process formula storage and call, the parameters can be added, modified, and saved up to 8000 sets of process parameters, which can be called at any time.

6) The system design locates the temperature range in a certain range, and takes the speed improvement as the main goal of structural optimization; The test proves that the coating of the equipment not only has high binding strength and high coating density, but also the surface stress is compressive stress;

7) The fuel flow of the system adopts full closed-loop design, modular design, high-performance PLC control, safe and simple operation;

8) Combustion design produces particles with a velocity of 1100 m/s (3300 to 3900 feet per second), which is significantly faster than other HVOF systems;

9) The thickness of the spray coating is greater than 10mm (compressive stress coating), and the microhardness is higher than that of other ordinary HVOF systems on the market (the microhardness of the HV-80s spraying WC-Co coating is as high as 1450, while the microhardness of the WC-Co coating sprayed by other gas HVOF spray guns is 900~1100);

10) HV-8000H model achieves excellent high pressure HVOF coating quality, and the coating can reach 70MPa binding strength.

- HVOF

- Inner Hole

- Touch Screen

- Full Closed Loop Design

- Coating Quality

Production Capacity:

10

Delivery Timeframe:

Within 30 Days

Incoterms:

EXW - Ex Works

Packaging Details:

Not informed

More about

Zhengzhou Lijia Thermal Spray Machinery Co., Ltd

50-100

Employees

2M - 10M

Sales volume (USD)

20%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

- Retailer

Keywords

- spraying

- Coating equipment

- electrical products

- technology transfer

Contact and location

-

tingyu ********

-

+86 1 ********

-

简体中文 / 郑州 | China