Description

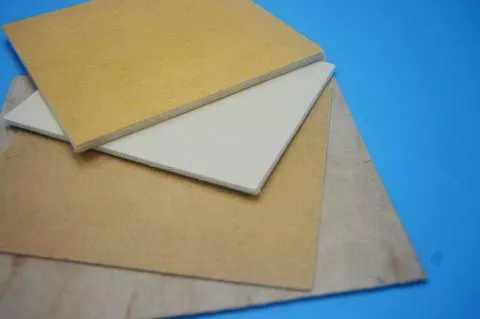

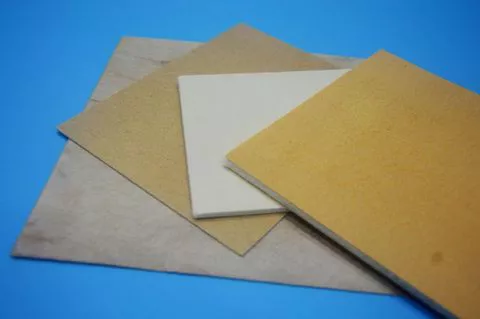

This product is a high-performance flame-retardant insulation board, which is formed by precision hot pressing process using glass fiber, inorganic binder and composite filler. It is specially developed for high-demand thermal management and safety application scenarios such as electric vehicles, electric heating equipment, and household appliances. This insulation board has ultra-low thermal conductivity, V0-level flame retardant performance, electrical insulation and excellent dimensional stability. It can effectively isolate heat sources, delay heat conduction, and ensure the safe operation of the system. It is an economical and efficient solution to replace traditional mica boards, foam boards and other materials. In terms of thermal insulation performance, the thermal conductivity of the material is as low as 0.025 W/m·K, which can significantly reduce the transfer of heat energy inside the structure and achieve more efficient thermal sealing and thermal insulation control. Compared with traditional materials, it has higher thermal insulation efficiency, while reducing cooling and heating energy consumption, improving energy efficiency levels, reducing operating costs, and extending the service life of the entire machine. Its superior thermal insulation effect makes it the preferred material for home appliance heating elements, battery thermal management systems, HVAC pipelines and other fields. In terms of safety performance, the product uses Class A inorganic raw materials and V0 flame retardant formula, has excellent flame retardancy and high temperature stability, can quickly self-extinguish in a fire environment, does not support combustion, and does not release toxic gases, ensuring the safety of equipment and personnel. The material has excellent electrical insulation performance and can effectively block the risk of current conduction. It is an indispensable insulation layer for electric vehicle power battery compartments, high-voltage electric control boxes, home appliance heating modules and other parts. In addition, its anti-aging, corrosion resistance, and moisture and heat resistance ensure that it can operate stably for a long time in complex environments, and is not easy to crack, deform or degrade. In terms of structural performance, the insulation board is a lightweight material with good plasticity and processability, suitable for cutting, stamping, bending, composite and other processes. Even in the face of complex equipment shapes and limited space, it can be accurately adapted through hot pressing molding to achieve fitting assembly and improve the sealing and mechanical consistency of the overall insulation system. The product can provide a variety of thicknesses, sizes and structural designs according to demand to meet the application requirements of different terminal products in terms of spatial layout and functional integration. Typical applications include: • Thermal isolation and fireproof insulation of electric vehicle battery modules and electronic control systems; • Inner cavity insulation layers of heating equipment such as ovens, electric kettles, and electric heating films; • Electrical insulation and thermal management systems for home appliances, electrical cabinets, and smart terminal devices; • Thermal sealing panels, duct linings, and energy efficiency enhancement components in HVAC systems. This flame-retardant thermal insulation board combines high-performance materials with advanced manufacturing processes to provide integrated thermal management and safety protection solutions for modern manufacturing, and is widely used in the field of electric and intelligent equipment manufacturing that pursues high safety, high efficiency, and high integration.

- Flame retardant insulation board

- electric vehicle insulation material

- home appliance thermal management board

- V0 flame retardant insulation layer

- glass fiber insulation material

- low thermal conductivity hot press board

- high temperature insulation board

- heating equipment insulation pad

- energy-saving fireproof insulation board

- battery thermal protection material

Production Capacity:

10000

Delivery Timeframe:

Within 30 Days

Incoterms:

CFR - Cost and Freight

CIF - Cost, Insurance and Freight

DDU - Delivered Duty Unpaid

EXW - Ex Works

FOB - Free on Board

Packaging Details:

Customizable

More about

Shenzhen Petersburg Composite Materials Co., Ltd

200-500

Employees

1M - 2M

Sales volume (USD)

30%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

Keywords

- thermal insulation

- fiberglass

Contact and location

-

Lionel ********

-

+86 1********

-

Shenzhen / Guangzhou | China