Description

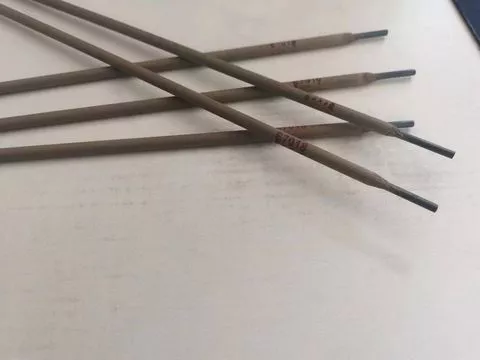

Model: E7018

Standards:

GB/T 5117 E5018

AWS A5.1 E7018

ISO 2560-B-E 49 18 A

Coating type: iron powder low hydrogen potassium type (AC and DC dual-use)

Peculiarity:

The arc is stable, the spatter is less, and the slag removal is easy

The deposition efficiency is high and the process performance is excellent

Good mechanical properties, can be welded in all positions (flat, horizontal, vertical, upright)

Uses: carbon steel and low alloy steel structure welding (such as 16Mn, etc.).

size

Diameter Φ: 2.5mm, 3.2mm, 4.0mm, 5.0mm

Length: 300mm, 350mm, 400mm

Reference Current (AC/DC+)

Electrode diameter (mm) Φ2.5 Φ3.2 Φ4.0 Φ5.0

Welding current (A) 60~100 80~140 110~210 160~230

Precautions

Pre-welding treatment: The electrode needs to be dried (350°C×1h).

Remove weldment oil, rust, moisture and other impurities.

Welding operation: short arc operation to avoid too long arc.

Welding slag needs to be cleaned during multi-layer welding.

- E7018 Welding Rod

- Carbon Steel Welding Rod

- Full Position Welding

- High Quality Welding Rod

- Low Alloy Steel Structure Welding

Production Capacity:

1000

Delivery Timeframe:

Within 30 Days

Incoterms:

EXW - Ex Works

FOB - Free on Board

Packaging Details:

2.5kg/box,8 box/20.0kg/Ctn 5kg/box, 4 box/20.0kg/Ctn

More about

Samgong Welding Materials

50-100

Employees

500K - 1M

Sales volume (USD)

20%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

Keywords

- Welding rods

- welding wires

- welding production equipment

- carbon steel welding rods

- E6013 welding rods

- welding rod production lines

- welding powder

- Welding Electrode Ver Mais

Contact and location

-

Tianjin ********

-

+86 1********

-

天津 / | China